Bent Crankshaft: What Are The Symptoms And How To Fix It

A crankshaft is an essential part of the car engine. It converts the up and down motion of the pistons into rotation motion to power the car smoothly. However, it’s prone to problems like bending. You must understand the signs and the solutions to fix the problem when this happens.

Contraction and expansion may make the crankshaft bend. This can be fixed by getting a remanufactured or new crankshaft. Alternatively, the old one can get repaired by a professional. Failure to fix crankshaft problems may cause damage to the engine parts, and the car may eventually fail to move.

The pistons push up and down in their cylinders during combustion, with connecting rods attaching them to the crankshaft. Its design allows the lower end of the connecting rods to move in a circular motion to turn the crankshaft.

This crankshaft rotation along a linear axis directs the car’s transmission to the driving wheels. It makes the vehicle move backward or forward. The crankshaft withstands a lot of pressure from the pistons and connecting rods or while transmitting power to the transmission.

How Is The Crankshaft Designed?

A crankshaft is made of a steel bar built through a forging or casting process. Some assembled crankshafts are made of various steel pieces attached. Others are machined from a single piece of remelted steel using lathes and melting machines.

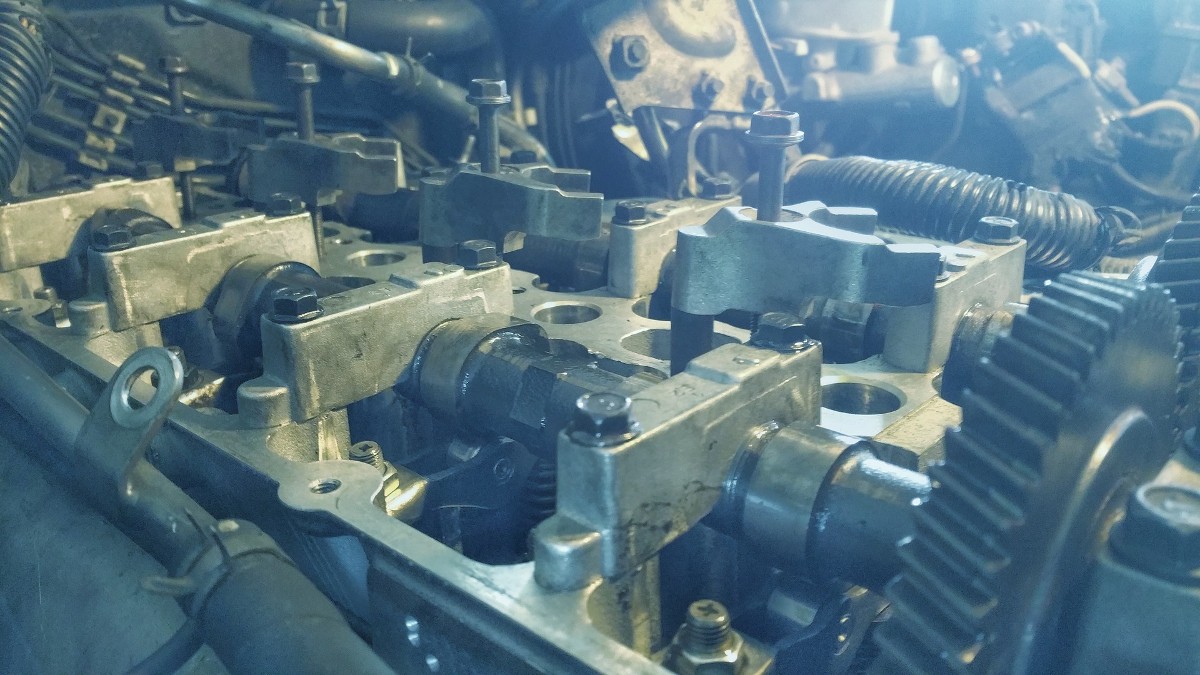

Various bearings hold the crankshaft inside the engine. The engine oil lubricates these bearings. The purpose of the bearings is to make the crankshaft spin smoothly in place. They also stabilize the crankshaft when exposed to powerful forces from the pistons and connecting rods.

What May Cause A Bent Crankshaft?

Extreme heat is one of the possible causes of a bent crankshaft. It may also result from alternating heating and cooling. Heat encourages contraction, while cooling leads to contraction. Exposure to these over time may make the crankshaft bend.

Bearing failure creates extra clearance making the crankshaft move freely within the engine. It encourages the crankshaft to bend and may damage other engine components. All these will require extensive fixing apart from replacing only the crankshaft.

Some operating conditions, including overspeeding or lugging, encourage the crankshaft to bend. Poor handling or dropping of the crankshaft before or during installation also leads to bending.

What Are The Symptoms Of A Bent Crankshaft?

Listening to the engine as it runs tells you your crank has a problem. A knocking sound during acceleration or other conditions indicates your crankshaft isn’t in good condition. A possible reason may be having issues with the connecting rod bearings.

Another alternative is to take the engine apart and inspect the crankshaft. Visually check to see whether the crankshaft is smooth and shiny without lines. You’ll like to see whether it’s okay or bent. When damaged, you must take it to the repair shop for grinding to accommodate the bearings.

There’s a possibility of the crankshaft breaking down the line. You’ll likely hear a knocking sound as the vehicle runs, depending on where it’s broken. The engine runs noisily when the crankshaft is broken along the main bearings.

Other signs to tell your crankshaft is failing include:

- Distorted bearing bore

- Loose-bearing main caps

- Poor bearing clearance

- Forging or casting flaw

All the signs above eventually make the crankshaft crack or break. When you notice these signs, the best thing to do is to stop immediately and have the car towed to a mechanic for a professional diagnosis.

How To Fix A Bent Crankshaft?

Depending on the severity of the problem, repairs may be cost-effective when your crankshaft is in bad shape. Here are pointers to fix your crankshaft.

If the crankshaft has damage, but everything in the engine is intact, you can have it replaced or replaced. You can get a remanufactured crankshaft which is more affordable than buying a new one. There’s also a chance to get one from the junkyard if your car has high mileage.

However, you must check the crankshaft bearings thoroughly to ensure they are still in great condition. Bad bearings have a likelihood of damaging a new crankshaft.

Extensive damage to the crankshaft and bearing takes a lot of work. Excessive wear may have resulted in the device’s round surfaces changing shape. A solution is to get a new or remanufactured crankshaft and bearings.

Sometimes the damage may be on the crankshaft, bearings, and engine’s top end. This is the most extensive form of crankshaft damage. The damage may have manifested on the crankshaft, bearings, connecting rods, and pistons.

If the pistons hit the cylinders, serious damage will likely happen to the intake and exhaust valves. You’ll end up with an expensive mess involving repairs on the engine, including the possibility of replacing the engine.

What Are Some Other Types Of Crankshaft Failures?

The crankshaft is also prone to other problems apart from bending, as highlighted below.

Torsional Fatigue

The crankshaft is prone to torsional fatigue resulting from the tension applying pressure on the conrod. It accelerates the crankpin and cranks slightly ahead of the crankshaft. A ripple travels the length of the crank, with the final resistance movement ending up at the flywheel.

A crankshaft has a natural resistance to this flexing. After the initial twist forward, a negative twist back is manifested. This becomes exaggerated on coinciding with the power pulses. It leads to fatigue failure or instant crankshaft failure.

Objects In The Air Holes

Some crankshafts have a brass restrictor in a cross-drilled hole on the crankpin. The restrictor sometimes comes out and damages the bearings.

Centrifugal Failure

This problem is quite rare, but it’s important to know. It happens when the engine is revved beyond the crankshaft’s ability to remain intact with the pulling force of the rods and pistons.

Because of the natural resonant frequency, the crankshaft may blow up into two or several pieces. The flywheel resits speed change due to inertia when the piston fires at the other end of the crankshaft.

What Are The Effects Of A Bent Crankshaft To An Engine?

A crankshaft rotates with large loads. A thin oil film is necessary to prevent metal-to-metal contact with the bearings. An oil wedge develops as the crankshaft turns, known as hydrodynamic support.

It results from the regular flow of oil from the oil pump. Any bend in the crankshaft disrupts oil and the overall performance of the crankshaft. This is because the clearance of the bearing to the crankshaft is 001 to 003 inches.

Final Thoughts

You can tell the crankshaft is bent when you hear noises from the engine. The right thing to do is to get a remanufactured or new crankshaft if your current one can’t be repaired. Eventually, your car may stop if you don’t have the problem fixed by a professional.