The mount keeps everything in place when your engine torques from a launch or a stop. Replacing a damaged mount is crucial to avoid problems in other parts of the vehicle. Let’s explain what you may need to know about engine mount torque specs.

A car engine has mounts to keep it securely in position. The mounts can’t be repaired or maintained if your car engine vibrates or has a rocky start. Knowledge of mount torque specs and the right wrench to use is crucial.

Torque specs are the set values for use on the wrench when replacing the engine mounts. Appropriate values are necessary for proper tension. This will ensure that the engine is secured in its position to avoid vibrations, visible wear, or noise while driving.

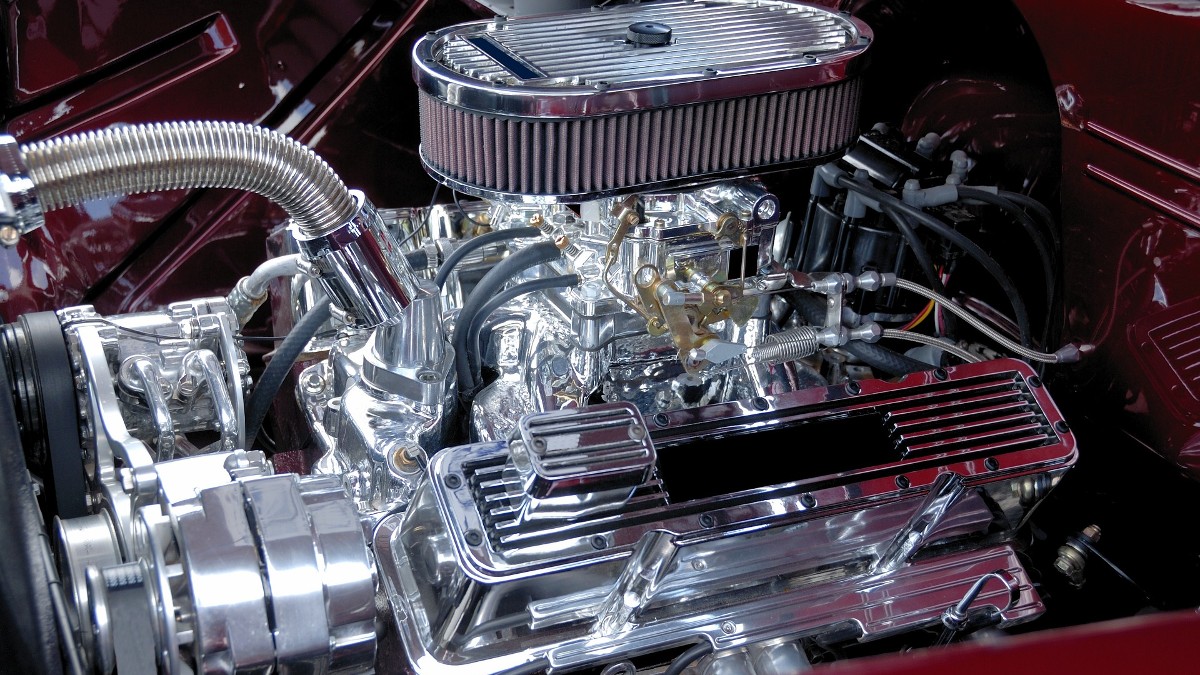

What Is An Engine Mount?

A mount is the part of your car engine that holds it in place. The mounts keep the engine and transmission secure. One mount holds the transmission, while two or three hold the engine. One engine mount attaches to the frame, and the other keeps the engine in place.

Rubber engine mounts limit direct contact between the engine metal and the car body. Filling the mount with liquid dampens any vibrations from the engine. Sometimes car manufacturers like Honda and Toyota use vacuum-controlled mounts for dampening.

A mount doesn’t need repair or servicing. Although it may last throughout the car’s life for some brands, the mount may need replacing after five to seven years. Common engine mount problems include rubber separating or breaking and liquid leaking from the mount.

How Do I Replace An Engine Mount?

The engine mount naturally breaks down after some time. You must always replace a worn-out mount immediately to avoid damage to other components like hoses, gaskets, wire connectors, and sensors. A weak mount encourages excessive engine movement leading to equipment failure.

Wherever you accelerate, you put pressure on the mount. Over time, the mount wears out. Excessive vibration from the engine signifies that you need to replace your mount. Replacing it is the best solution to fix the problem before it escalates.

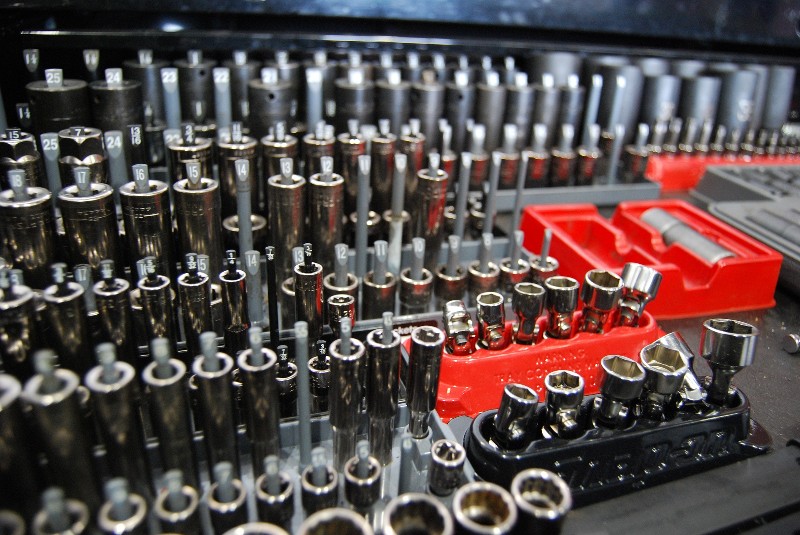

What Is The Ideal Wrench For Replacing Engine Mounts?

Installing a mount requires using a torque wrench to tension the fasteners. The wrench allows for making the final adjustment after equalization and aligning. Two wrenches are necessary, one for steadying the adjusting nut and the other for tightening the lock nut for proper tension.

A torque wrench indicates when you have reached the particular specs with an audible click beep. Alternatively, you may feel some tactile feedback through your hand. You must select the required specs on the wrench handle. The wrench is long to reach high torque when required.

What Are The Different Types Of Torque Wrenches?

Torque wrenches for replacing engine mounts come in sizes including 1/4inch, 3/8inch, and 1/2inch models. This is the size socket where they are applicable, but a larger drive requires a larger wrench for more leverage. You must choose a wrench that will make your work easier.

To use the torque wrench for the first time or after spending time without use, run it to keep the internal parts and have it well lubricated. Set the torque to a high setting before activating it five to ten times. The internal parts will become free, and the lubricant will move around.

What Are The Specs For Engine Mount Torque?

Engine movement and misalignment are signs of mount failure. Broken or worn mounts may cause your car engine to move around in all directions during acceleration or driving at high speed. You must replace the mounts to prevent this from happening.

Replacing engine mounts requires using a torque wrench. However, you must use the appropriate torque specs for a secure mount. A torque wrench has a locking mechanism to prevent bumping around the device’s specs.

Before you begin using the wrench, you must unlock the lock mechanism. Equally important is understanding the appropriate torque specs. After getting this, twist the wrench handle until its edge lines up with the value you desire for the task.

You must align zero to the appropriate specs, then twist the torque wrench handle for the edge to line up with your desired value. Increments for each wrench are different. Here’s a table with mount torque specs.

| Upper Engine Mount | |

| 2- 18mm nuts | 74 ft-lbs (100 N-m) |

| 3- 15mm bolts | 37 ft/lbs (50 N-m) |

| Front trans mount | |

| Mount to trans | 66lb- ft |

| Through bolt | 74lb-ft |

| Rear tran mount | |

| Mount to frame | 44lb-ft |

| Through bolt | 74 lb-ft |

How To Use The Torque Wrench?

After knowing how to set the wrench to your desired specs, it’s time to understand how to use the tool. The wrench has a ratcheting function for quick fastening. Never use the wrench for loosening fasteners.

When the mounts become tight, apply even steady pressure until the wrench clicks.

You will hear and feel the click. Afterward, release and apply pressure gently for the wrench to click a few more times. This ensures that you have reached the appropriate tension.

After using the wrench, return it to a neutral setting to release the tension on its internal spring.

Should I Replace All Mounts At The Same Time?

You don’t have to replace all mounts at the same time. You just have to check and see those in bad shape and replace them. Remember that they are likely to be the same age. After replacing one, you’re likely to replace the others after a short while.

When one mount is damaged, it puts pressure on the others. This makes them wear out much faster. So, replacing more than one mount is a wonderful idea. You must get a professional mechanic to give you expert advice.

If your engine has increased vibrations and gives you a bumpy ride, your mounts may need replacing. You can’t repair or maintain the mounts. Replacing is recommended, and knowledge about the appropriate specs and a torque wrench is necessary for the appropriate tension.