A flywheel is a heavy disc attached to the end of the rotating shaft to smoothen out the engine’s power pulses and store energy through rotational momentum. Read our explanation below if you’ve been wondering how to turn a flywheel by hand.

Turning the flywheel by hand requires having the transmission in neutral. You must loosen the crankshaft bolt using a socket wrench and turn it clockwise. It’s now possible to turn the flywheel by hand fairly easily, although there’s bound to be some pressure.

A manual transmission car seems to have an essential mechanical design. However, it has various parts regularly in motion to keep it under control. One is the flywheel, a thick metal disc that is extremely rigid to prevent warpage or flexing while in use.

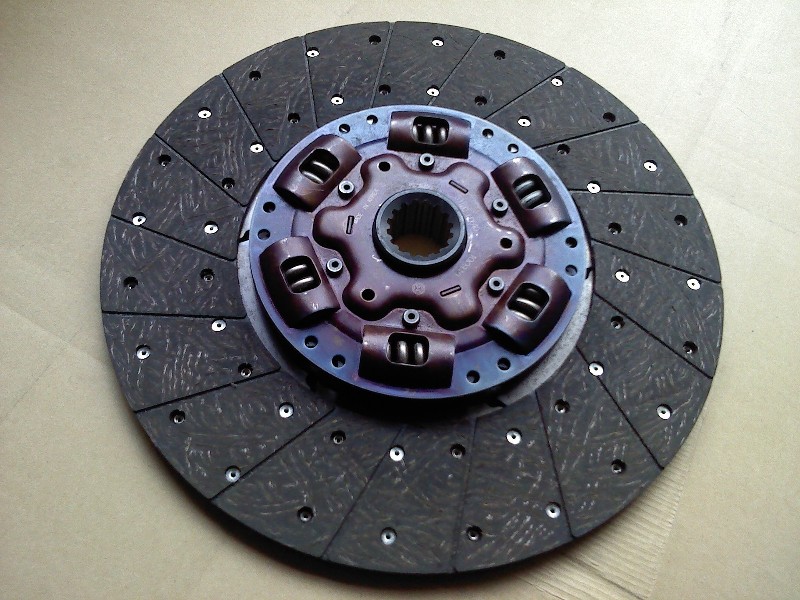

The flywheel has gear teeth on edge to engage the starter motor. It’s firmly bolted to a flange on the transmission side of the crankshaft inside the bell casing. The surface is designed flat on the side facing the transmission to allow attachment by the clutch disc.

What Does The Flywheel Do?

The flywheel offers the necessary mass to give the engine rotational inertia to run. When you put your feet off the accelerator, it prevents the engine from stalling. The flywheel handles engine balancing because it’s weighted on the crankshaft to eliminate the rough feeling resulting from imbalance.

Your car’s starter motor engages the flywheel ring to rotate the engine. The flywheel also connects the transmission to the engine through the clutch, transferring power to the wheels.

What Are The Types Of Flywheels?

There are basically two types of flywheels:

Lightened Flywheels

These have changed engine dynamics in motorsport and track-modified cars. Making these flywheels requires removing excess material from older variants with cast iron. These are replaced by aftermarket options made from steel for your particular car.

The low mass makes the flywheel rotate much easier under the engine’s power. It makes it ideal during acceleration in lower gears to allow hanging engine speed rapidly; lightened flywheels are common in cars that need perkier powertrains when changing a gear instead of hanging.

The absence of inertia makes the engine speed drop swiftly. It increases with the accelerator pedal’s slightest flick to allow smooth downshifting by rev-matching. The reduced mass slightly compromises engine turnover’s smoothness, but weight reduction is ideal for motorsport cars.

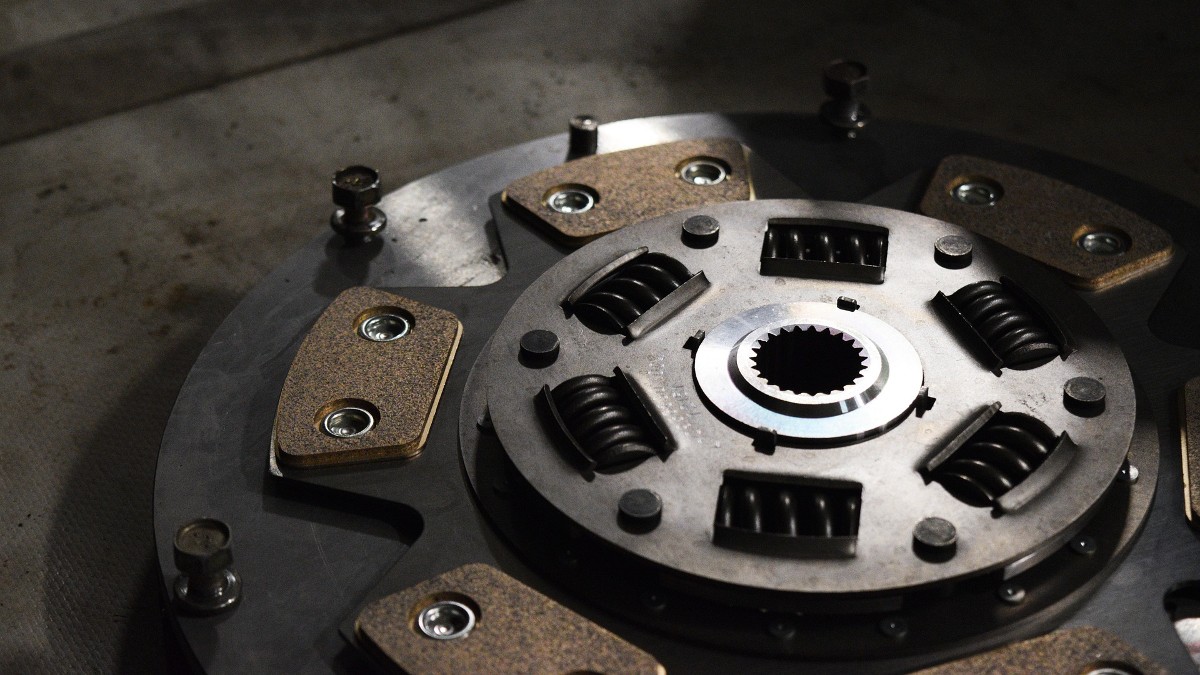

Dual Mass Flywheel

It’s the opposite of a lightened flywheel with extra mass. A dual-mass flywheel combats unwanted vibrations that may hamper the functioning of other components. The flywheel dampens the effect through the dual mass and various springs.

One mass connects to the crankshaft, and the other to the transmission. The primary mass is a large disc rotating with the crankshaft, while the second disc is smaller, sitting within it. Springs connect the two masses.

The primary mass spins as the springs make the second one also rotate. The springs eliminate any vibrations before reaching the second mass and through transmission.

What Are The Parts Of A Flywheel?

Now that you know the types of flywheels, it’s time to understand their parts.

Flywheel Housing

The solid external part of the flywheel keeps the internal components safe and protected from any damage. The housing also allows easier handling of the flywheel.

Planet Wheel

This includes various planet gears attached to a flywheel holder. Actuating and rotating the flywheel mount screw engages the outer ring gear. It creates a compound motion composed of each gear revolution and rotation.

Springs

A flywheel has two-phase springs arranged in parallel. An adjusted outer arc raises the spring as the engine runs. A soft outer bow spring improves the unsafe resonance frequency range.

Ring Gear

It attaches to the outer diameter of the flywheel. Fixation is usually done with the help of an interface fit created by heating the gear. The thermal expansion allows the placement of the ring gear around the flywheel.

Bearings

These include axial and radial plain bearings. Axial bearings are for balancing weight. The radial bearings manage imbalance or parasitic radial force from the motor or generator unit.

Sliding Shoe

A flywheel has sliding shoes with a convex radial outer surface resting against its inner wall. The shoes are built to promote slipping and resist wear.

Support Disc

It’s placed on the flywheel to support the springs and other components.

Flywheel Cover

Usually made of chrome, the flywheel cover protects the internal functions of the component from rusting.

What Problems Can Happen On The Flywheel?

Heavy duty construction of the flywheel makes it extremely durable. However, it may incur some problems, although less frequent. Contamination is a common problem on the flywheel resulting from a leaking crankshaft or transmission front input seal.

An oil leak on the flywheel causes slippage on the clutch and excessive friction, which encourages heat. It leads to warpage or hot spots that create vibrations on acceleration and engagement. The flywheel may also crack because of its hard use in high-performance cars.

How To Turn a Flywheel By Hand?

If you have issues with your transmission, you must get a professional mechanic or know how to separate the transmission from the engine block. Doing it yourself requires spending time underneath the transmission.

A car transmission uses a torque converter to transfer spinning energy from the crankshaft to the transmission. Turning the flywheel gives access to the bolts securing the torque converter to the flywheel to remove the transmission for repair.

Here are the steps to remove the transmission by hand.

Step 1: Access The Engine

Open the hood by standing on a ladder to get to the engine. Place a ratchet and socket wrench into the engine’s front compartment housing the main pulley or radiator fan. Remove the protecting plastic cover and shields to prevent using the extension bar when secured.

Step 2: Sit In The Driver’s Seat

The position of the flywheel and bolt placement must be removed to separate the torque converter from the flywheel. Clear away all moving parts with the help of an assistant, and you can tell whether the flywheel movement is smooth or challenging.

Step 3: Insert The Ignition And Turn The Engine

The engine will activate the starter, which uses the flywheel to crank the engine to start. However, it strains the engine leading to erratic movement. Turn the flywheel until it’s in place.

It’s bolted to the crankshaft rear, and you must remove the spark plugs from the engine to eliminate compression to turn the flywheel by hand.

Final Thoughts

The flywheel smoothens energy pulses from the combustion in the cylinders giving energy to the pistons’ compression stroke. You can turn the flywheel by hand, as you’ve noticed in our step-by-step guide above.