What Is A Crankshaft Throw? How To Determine The Number Of Engine Crank Throws?

There are various things you may not know about your car, especially the engine since it has various components. Perhaps you’ve heard about crankshaft throw and wondered what it is. Would you like to know how to determine the engine crank throw number?

Engine throw is the distance from the center of the main journals and the crankshaft pin center. Determining the crankshaft throw requires measuring the distance between the center of the crank pins and the center of the main bearings.

What Is A Crankshaft?

An engine has various parts, including the crankshaft. This engine component converts the piston’s reciprocating motion into rotational motion. The rotary motion goes to the flywheel to generate the appropriate torque for its operation.

A connecting rod attaches the crankshaft to the piston. The crankshaft is an essential component of an engine for purposes including

- Driving various components, including radiator fan and camshaft

- Gives motors with multi-cylinders a smoother drive

- Converts upward and downward motion of the pistons into rotational motion

- Produces power through the combustion of the air/fuel mixture

- Bears load for distribution during combustion

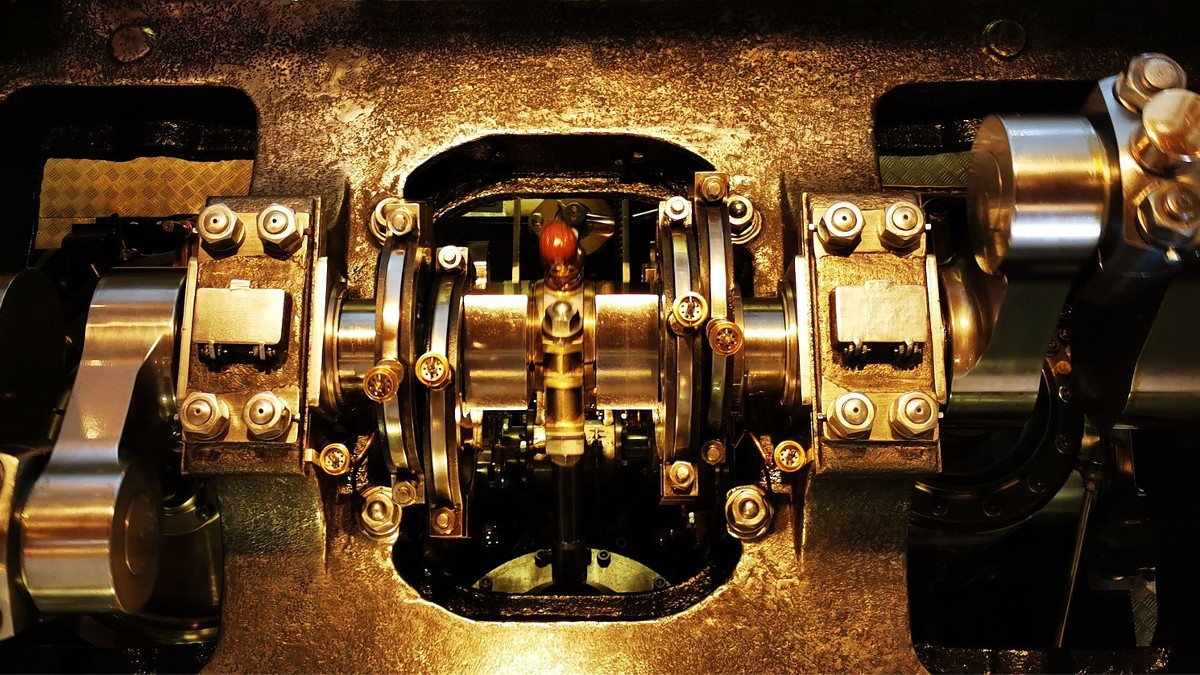

What Are The Essential Parts Of A Crankshaft?

A crankshaft plays an essential role in the engine. The crankshaft throw determines the piston stroke.

Main Journals

The main journals are the crankshaft components that keep it attached to the engine block. Journals are arranged in a straight line or linear to each other. The journals are the end bearings below the connecting rods opposite the pistons.

They connect to the counterweights through plates known as webbing. The counterweights are for balancing the crankshaft load while in motion.

Crank Pins

The crank pin is the crankshaft component that supports the connecting rod to attach to the crankshaft firmly. Crank pins supply rotative force to the connecting rod for maximum efficiency. They transfer up-and-down movement from the crankshaft to the connecting rod.

Main Bearings

The main crankshaft bearings support the crankshaft rotation under inertia forces from shaft components and oscillating forces from the connecting rods. They are mounted on the crankcase and have the upper and lower part.

When the main bearings fail, it increases pressure, heat, or metal-to-meta contact. This causes distortion of the crankshaft and connecting rods and eventual engine seizing. Signs of worn-out bearings include low oil pressure and knocking noise.

Flywheel Mounting Flange

Mounting flanges attach the crankshaft to the flywheel. The crankshaft diameter on the side of the flywheel is greater than the other side. This allows the flange to mount the flywheel easily. The flywheel edge has gears for engaging the engine’s starter motor.

How Does The Crankshaft Work?

The camshaft rotates when the engine powers on, making the lobes connect with the engine lobes to open the engine valves. During the engine cycle, the valves close and open for the air/oil mixture to enter the cylinder and for exhaust gasses to leave.

The valves have springs that decompress to close them after the lobe opens. A timing belt synchronizes with the engine movement to time the camshaft. Opening the vale syncs with the engine cycle to avoid mistiming which may damage the valves and cylinder.

A crankshaft converts force generated by engine combustion into rotary motion. The connecting rod converts the piston’s upward and downward linear motion into torque for transmission to the flywheel.

What Is a Crankshaft Throw?

The crankshaft throw is the distance from the center of the primary journal and the crankshaft pin. The main journal carries the main bearings to declare the axis rotation axis. Crank pins support the attached connecting rod.

Throw determines the engine stroke, and one throw is half a stroke. A longer throw means a more powerful stroke or a longer distance traveled by the distance. Crankshaft throw is very important for determining the piston stroke.

What Are The Types Of Crankshaft Throws?

As highlighted below, a crankshaft throw is either a single or multi throw depending on the crank pins.

Single Throw Crankshaft

Also known as a 360-degree throw, a single throw is usually for single-row radial engines. Just like the name, a single-throw crankshaft has a single crank pin and two main journals supporting the crankshaft in the crankcase.

This throw may have one or two crankshaft pieces held together by a bolt passing through the crank pins.

Two Crankshaft Throw

This throw is common on twin-row radial engines, with each bank of cylinders having one throw. The two-throw crankshaft usually has thrown 180 degrees from each other. This throw may have one or three crankshaft pieces.

A two-throw crankshaft may be cranked or thrown in two opposite directions. The throw has two cranks sitting opposite each other.

Four Throw Crankshaft

A four-throw crankshaft is for four-cylinder opposed engines or four-cylinder in-line engines. The crankshaft is usually for horizontally opposed engines machined as a single piece. For this type of crankshaft, the throws are 180 degrees apart.

Six Throw Crankshaft

This type of crankshaft is usually for six-cylinder opposed, in-line, and 12-cylinder V-type engines. The throws for this crankshaft are 60 degrees apart. The crank journals may be numbered from the flanged end.

How Do I Determine The Number Of Engine Crank Throws?

There are no one-size fits all solution to determine the number of crankshaft throws for each engine. Here’s a simple process to determine the throw of an engine.

- Remove the spark plug

- Get a lengthy piece of wire or rod

- Place it into the spark plug

- Maintain a parallel position on the cylinder bore while measuring

- Rotate the crankshaft and measure the highest point traveled by the piston

- Determine the lowest position moved by the wire

- Divide the total movement by two to get the crankshaft throw

The crankshaft is an essential component of an engine. It converts reciprocal motion from the piston into rotational motion. Crankshaft throw determines engine stroke. And requires measuring the distance between the centers of the crank pins and the center of the main bearings.